Advanced Physical Layer (APL): Ethernet into the field level

Ethernet APL technology is revolutionizing the possibilities of data transmission in the process industry, as for the first time it is possible to communicate directly at field level at a speed of up to 10 Mbit/s and with a homogeneous protocol. The physical level enables power supply in parallel to communication via conventional two-wire connection technology and is suitable for use in intrinsically safe hazardous areas.

Development of the new communication standard

Right from the very start when the Ethernet-APL Consortium was founded in 2018, SAMSON was involved as an industry partner in the development of the technology and active member of the steering committee. It was the first time in the history of the process industry that all leading industry standardization organizations – FieldComm Group, OPC Foundation, ODVA and PI (PROFIBUS & PROFINET International) – as well as twelve renowned suppliers of process control systems, infrastructure technology and field devices worked together on one project. Back in 2016, SAMSON built the first APL demonstrator for the Valve World Expo. It is still on display in the Digital Lab at our ROLF SANDVOSS INNOVATION CENTER in Frankfurt and used for testing purposes. The official launch of the new Ethernet-APL technology took place during the virtual ACHEMA Pulse show in 2021.

Technology

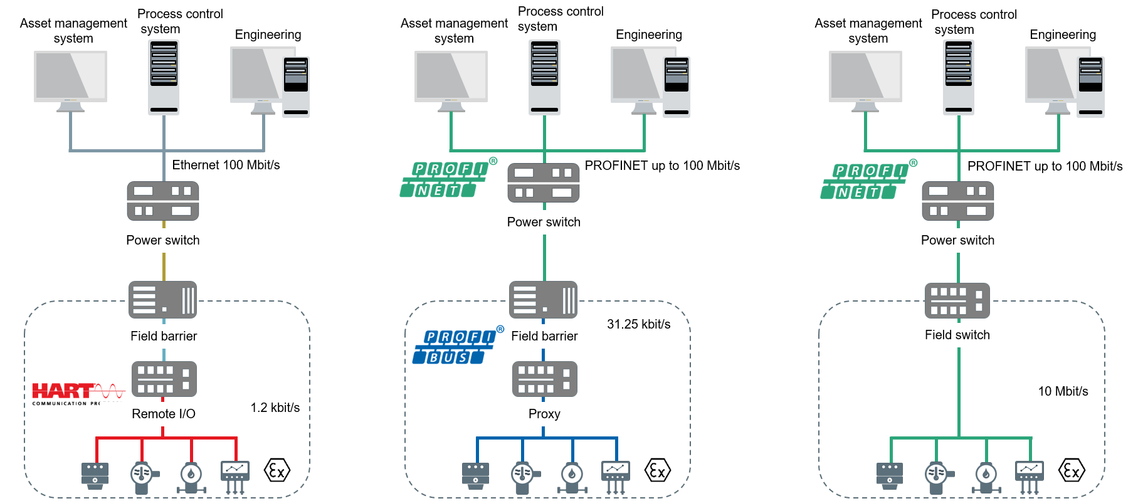

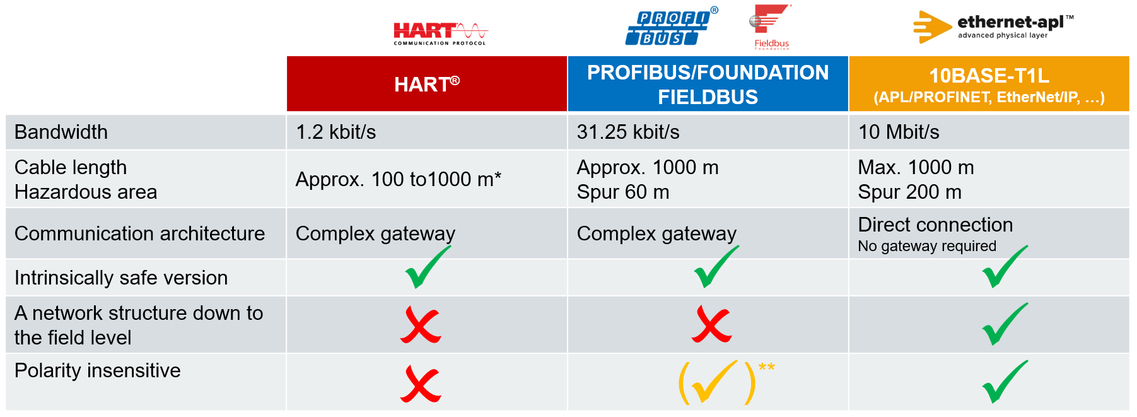

The Advanced Physical Layer (APL) describes a physical transmission layer, which makes homogeneous Ethernet communication possible all the way down to field level and in hazardous areas. Conventional fieldbus Type A cables, which comply with IEC 61158-2 requirements, can be used. The two-wire installations are suitable for intrinsically safe zones and have reverse polarity protection. They allow 10 Mbit/s communication and power supply over one single cable.

Ethernet-APL supports all commonly used Ethernet-based protocols, such as EtherNet/IP™, HART-IP™, OPC UA and PROFINET®, effectively made possible by the collaboration of the four leading standardization organizations (FCG, ODVA, OPCF, PI). One big advantage of bringing Ethernet into the field is the use of a homogeneous protocol at all levels. It makes protocol converters in the plant architecture redundant. This helps streamline the network architecture.

Advantages

After just three years' collaboration work, the Ethernet-APL Consortium was ready to announce the launch of the Ethernet-APL technology at the ACHEMA Pulse show in 2021. The advantages of the new technology include communication down to field level, a reduced infrastructure complexity and a data rate of 10 Mbit/s to transfer process and device data using conventional two-wire installations. It also supports intrinsic safety in hazardous areas (2-WISE). It allows communication over distances of up to 1200 m. Data can be practically accessed in real time thanks to the communication across all levels of the plant and the fast data rate.

The functions that are implemented in the PROFINET Profile 4.0 facilitate start-up since less network configuration and installation work is involved. The Ethernet-APL technology involves a high degree of standardization and is based on the exact definition of components. This significantly simplifies the search for suitable components within a plant.

Communication down to field level is practically "live" thanks to the fast data rate of 10 MBit/s. Plant operators are able to make the right decisions based on in-depth insight into plant operations provided by the technology. The standardized high-speed communication over all levels makes the overall plant status accessible in real time. Fast and straightforward access to device, process and diagnostic data supports predictive maintenance since anomalies can be identified at early stage before they can cause equipment failure.

Our positioners based on Ethernet-APL technology

TROVIS 3797

Our TROVIS 3797 Positioners with PROFINET® communication are the first SAMSON positioners to support the new Ethernet-APL technology. This positioner model is based on the high-end Series 379X positioner platform. Optional modules can added to the positioners, for example to achieve a higher air capacity for both single- and double-acting actuators. The addition of optional pressure sensors enhances the capabilities of the proven, fully integrated valve diagnostics to ensure safe and reliable operation.

This might also interest you

SAM DISTRICT ENERGY

SAM TANK MANAGEMENT

Control valves

SIL

MainChange

Volume boosters

Quick exhaust valves

Differential pressure meter

Positioners

Actuators

Industry 4.0

FDI

Careers

Pilot valve

Self-operated regulators

SAM LAN

Automation

Supervisory Board

Hydrogen

Media

Hook-ups

Commitment

Valve accessories

Supply pressure regulators

Automation systems

Seminars

Executive Board

Sales offices

Globe valves

Vocational training

Digitalization

SAM DIGITAL

Headquarters

Subsidiaries

Solenoid valves

Lock-up valve

SAM GUARD

Service

Limit switch

Valves

Conference