Hook-ups: detailed engineering of the control valve assembly

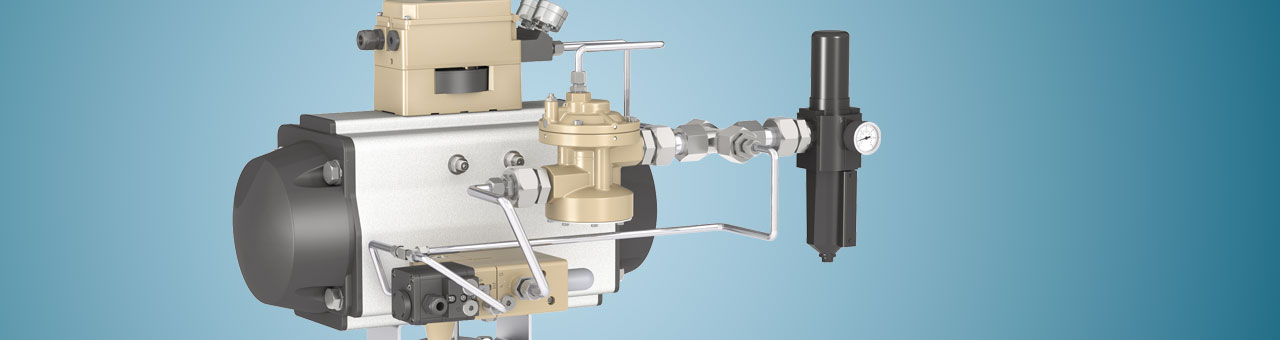

In addition to the wide variety of high-quality products in our program, we also offer control engineering for the entire valve assembly. You can benefit from our expertise.

Valve accessories are hooked up to achieve the required function of the valve assembly. At SAMSON, we have already implemented over 500 different hook-ups that have proven reliable in field use.

Our engineering specialists rely on proven compact hook-ups for standard applications to avoid complicated piping wherever possible. This results in cost-optimized solutions and the best possible control performance since signal transit times are minimized.

While a compact design is aimed for in standard applications, an absolutely reliable engineering to achieve the best possible interaction between all components is necessary for special applications and to meet complex requirements. Conditions, specifications and the features of the devices used are combined to form dependable valve assemblies. To create assemblies that meet the control requirements, we can rely on the extensive product portfolio of SAMSON and its subsidiaries as well as specifically developed software tools to simulate the transit times and control behavior beforehand.

Test benches to verify the required properties on the mounted valves round off the engineering expertise provided by SAMSON.

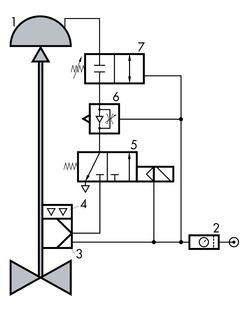

Lock-up function with priority

The example shows a valve assembly for control, with quick-acting shut-off and fail-in-place functions.

As the last device connected upstream of the actuator, the lock-up valve takes priority. Regardless of the positioner‘s signal and the solenoid valve‘s position, the lock-up valve causes the actuator to remain in its last position as soon as the supply pressure falls below a certain limit.

The opening and closing action is accelerated by the volume booster, which boosts the positioner‘s control signal accordingly. When using the Type 3755 Volume Booster, it supplies the actuator with an air flow output whose pressure corresponds exactly to the signal pressure of the positioner, except that it has a much higher volume.

The quick-acting shut-off function is performed by the solenoid valve, which is activated by the volume booster in the example. The supply pressure regulator provides the devices in the hook-up with a constant supply pressure.

1 Actuator – 2 Supply pressure regulator – 3 Positioner – 4 Limit switch – 5 Solenoid valve – 6 Pneumatic volume booster – 7 Lock-up valve

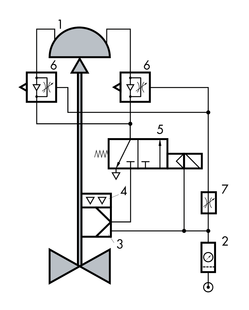

Adjustable closing time

The example shows a valve assembly for control with adjustable closing time and quick opening function.

By using two volume boosters, the opening time of the control valve, in particular, is accelerated. The closing time can be adjusted within a certain range at a separate restriction.

The solenoid valve activates the two connected volume boosters to implement the quick opening function. When the solenoid valve is energized, the control valve is in closed-loop control: the positioner supplies both volume boosters with a control signal, which is boosted accordingly. The supply pressure regulator supplies a constant supply pressure.

1 Actuator – 2 Supply pressure regulator – 3 Positioner – 4 Limit switch – 5 Solenoid valve – 6 Pneumatic volume booster – 7 Restriction

Together with valve accessories, pneumatic control valves serve as engineered solutions for special applications. SAMSON has been developing and manufacturing high-quality valves, actuators and valve accessories for over 100 years. Thanks to our experience and expertise as well as customer requirements, we have continuously developed the individual components and optimized their interaction.

Click here for information on valve accessories:

This might also interest you

Self-operated regulators

Differential pressure meter

Headquarters

Hydrogen

Control valves

Sales offices

Automation

Industry 4.0

Pilot valve

Executive Board

Volume boosters

Supply pressure regulators

SAM LAN

FDI

Media

Valves

Automation systems

Seminars

Vocational training

Globe valves

Supervisory Board

SAM GUARD

Positioners

Valve accessories

Digitalization

Lock-up valve

Commitment

Service

Hook-ups

Careers

Subsidiaries

MainChange

SAM DIGITAL

Conference

Solenoid valves

SAM TANK MANAGEMENT

Actuators

Quick exhaust valves

SAM DISTRICT ENERGY

SIL

Limit switch