Quick exhaust valves: used to reduce the venting time

Quick exhaust valves are used to reduce the time required for venting pneumatic actuators.

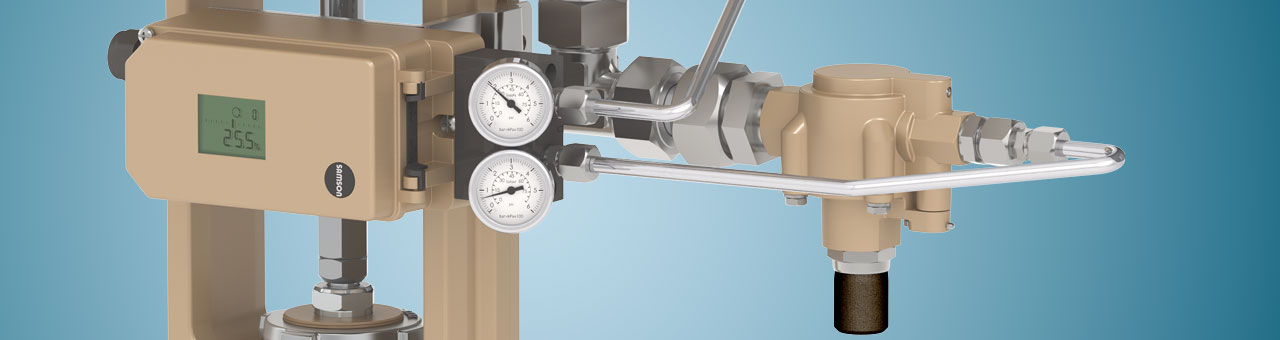

The Type 3711 Quick Exhaust Valve features a particularly compact design and a high flow coefficient. The integrated restriction allows the response of the valve to be adjusted to meet the requirements of the application.

If required, the exhaust air can be discharged through a pipe and, for example, fed back for purging of the actuator spring chamber.

Adjustable response behavior

The quick exhaust valve is mounted between the positioner or solenoid valve and the pneumatic actuator. It is used to accelerate the venting capacity to vent the pneumatic actuator more quickly.

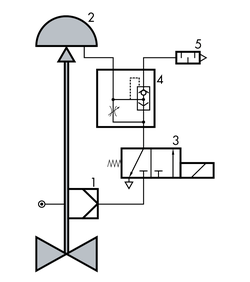

The example shows a standard hook-up with activation by a positioner and an additional solenoid valve connected between the positioner and quick exhaust valve.

The integrated restriction allows the response behavior to be tuned optimally to adapt the Type1 3711 Quick Exhaust Valve to individual valve assemblies and their control behavior. For example, opening the restriction causes the quick exhaust valve to intervene in the closed-loop control after large signal changes occur. This counteracts overshooting, especially in response to small signal changes. A cotter pin secures the restriction setting.

1 Positioner – 2 Pneumatic actuator – 3 Solenoid valve – 4 Quick exhaust valve – 5 Silencer

Together with valve accessories, pneumatic control valves serve as engineered solutions for special applications. SAMSON has been developing and manufacturing high-quality valves, actuators and valve accessories for over 100 years. Thanks to our experience and expertise as well as customer requirements, we have continuously developed the individual components and optimized their interaction.

Click here for information on other valve accessories and hook-ups:

- Positioners

- Limit switches

- Solenoid valves

- Lock-up valves

- Supply pressure regulators

- Volume boosters

- Hook-ups

This might also interest you

Digitalization

Media

Actuators

Seminars

Hydrogen

Control valves

Service

Positioners

Industry 4.0

Supervisory Board

Supply pressure regulators

Headquarters

Subsidiaries

Vocational training

Differential pressure meter

SAM TANK MANAGEMENT

Pilot valve

FDI

SAM LAN

SAM GUARD

Valves

Volume boosters

SAM DISTRICT ENERGY

Automation

SIL

Conference

Executive Board

Lock-up valve

Commitment

Valve accessories

MainChange

Limit switch

SAM DIGITAL

Automation systems

Globe valves

Hook-ups

Solenoid valves

Careers

Self-operated regulators

Sales offices

Quick exhaust valves