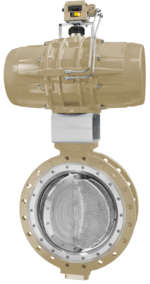

Triple Offset Control and Shut-off Butterfly Valves

Advantages

- At the slightest rotary motion, the seal is lifted off the body seat, which means that there is no transition from static to kinetic friction between the seat and conical seal geometry.

- The conical seal shape prevents the butterfly disk from getting jammed.

- The control and shut-off butterfly valve can be used for both directions of flow:

- FTC = flow-to-close (the medium helps to close the disk)

- FTO = flow-to-open (the medium helps to open the disk)

- The seat's conical shape ensures maximum shut-off performance even at extreme temperature fluctuations and pressure peaks.

- The valves have an extraordinarily long service life since they open and close almost without friction and mechanical initial breakaway torque.

- Thanks to their patented disk profile (patent no. DE 10 2012 102 4720 A1), the control and shut-off butterfly valves are also suitable for use in supercritical processes.

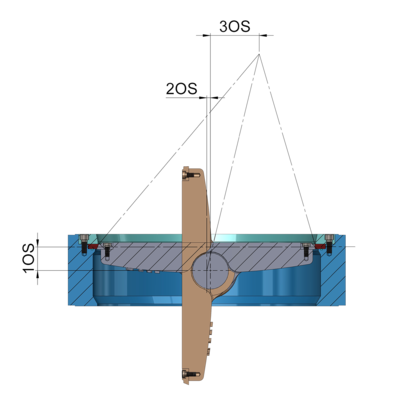

Triple-offset design principles

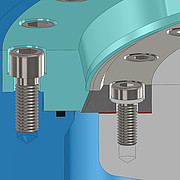

Offset between the center line of the shaft and seat ring

The shaft is mounted completely behind the facing of the disk and seat. The result is one continuous, uninterrupted facing. This provides a tight shut-off to be achieved as there are no more transitions between disk and shaft in the sealing area.

Offset between the center lines of the shaft and body

The shaft is positioned with a slight offset from the center line of the body. This gives the butterfly valve a flow-to-close (FTC) and a flow-to-open (FTO) closing direction. If the butterfly valve is installed in the standard FTC direction, the process medium helps keep the disk shut and press it into the conical seat.

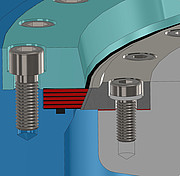

Offset of the axis of the seat to the center line of the body

The beveled conical seat geometry allows for an almost frictionless rotary motion and reduces wear and tear when the valve is opened or closed. Breakaway torque caused by deformation can be ruled out. The conical facing ensures strict seat leakage requirements can be met.

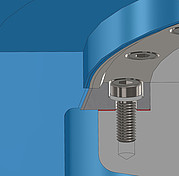

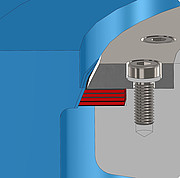

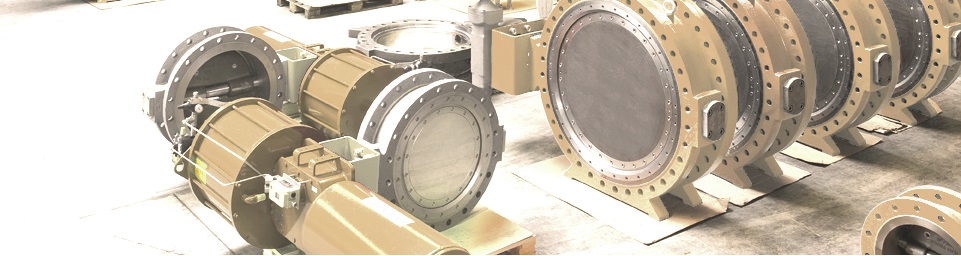

Series 2 (LEUSCH standard)

The seat (labyrinth seal, 4) inside the body, which is protected against the medium flow directly into it, and the solid seat ring (3) can be replaced as the retaining ring (5) is removable.

- Best solution for critical applications, such as control involving strict seat leakage requirements

This might also interest you

FDI

Quick exhaust valves

Executive Board

SAM GUARD

Lock-up valve

Self-operated regulators

Control valves

Hydrogen

SAM LAN

Supervisory Board

Globe valves

Pilot valve

Valves

Vocational training

MainChange

SIL

Automation

Supply pressure regulators

Industry 4.0

Valve accessories

Positioners

Differential pressure meter

Digitalization

Service

Actuators

Hook-ups

Volume boosters

Limit switch

Subsidiaries

SAM DIGITAL

Headquarters

Solenoid valves

Automation systems

Seminars

Careers

Commitment

Media

Sales offices

SAM DISTRICT ENERGY

SAM TANK MANAGEMENT

Conference