CRYOGENIC APPLICATIONS

Designed for Cryogenic Service

Industry, medicine, supply engineering and research: the fields of application and quantities of industrial gases consumed vary immensely. Consequently, the most important factor for a successful gas supplier is the location of its production site, either as on-site gas generation directly at the customer's or a central plant with a pipeline network. The strict technical regulations make it necessary to use constructions that exceed the limits of conventional products.

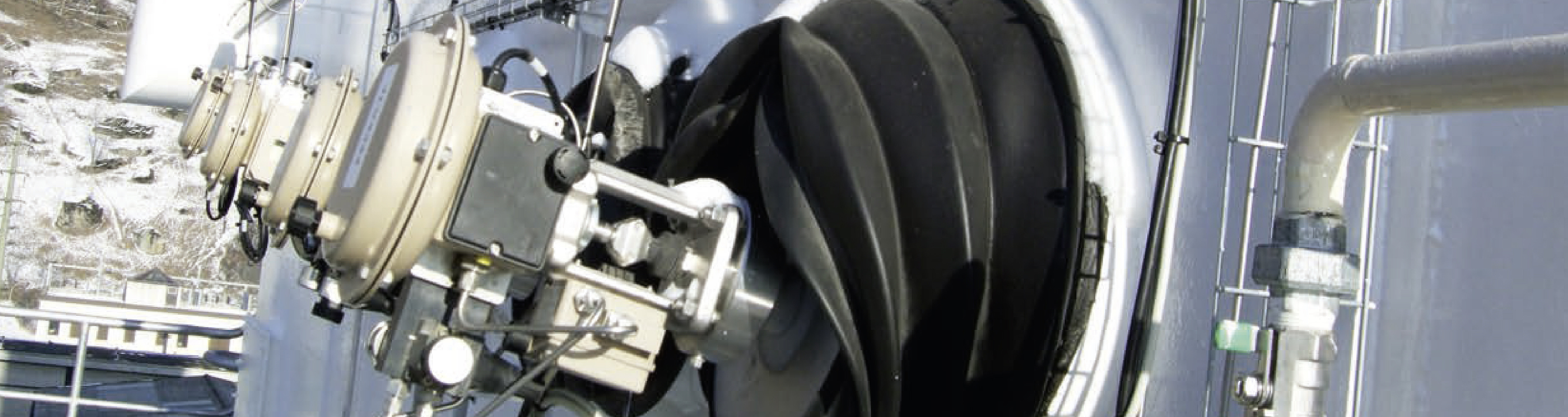

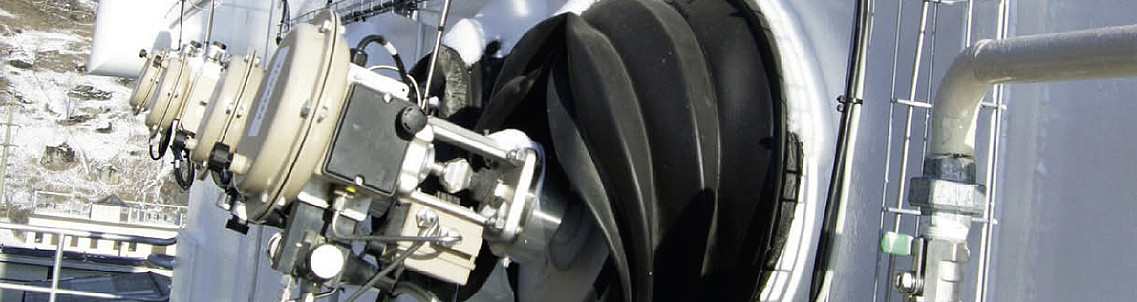

Cryogenic valves

SAMSON's cryogenic valves were specifically developed to meet the strict requirements of cryogenic applications. Fitted with insulating section or bellows seal, they can be used at temperatures down to –270 °C, for example in liquid helium service. Thanks to the valves' flexible design, SAMSON is capable of supplying the right overall heights and connections for every plant.

The Types 3598 and 3248 come with top-entry design as standard. This means that the metal bellows, seat and plug can be replaced while the valve up to the height of the cover plate can remain enclosed or insulated.

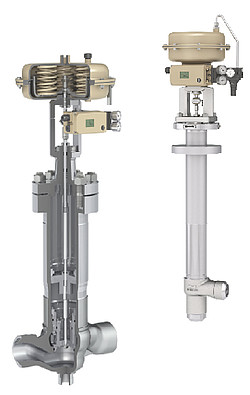

Type 3598

- Suitable for cold-box use

- ANSI version

- Top-entry version (standard)

- Cage-guided globe valve for simplified servicing

- Pressure-balanced plug as standard to reduce the actuator thrust required

- Minimized heat leak thanks to the use of a circulation inhibitor and a cryogenic extension bonnet

Helpful links:

Optimised cryogenic valve

Keeping cool when controlling cryogenic media

Source: cpp 01-2020

Type 3248

- Suitable for cold-box use

- Versions in globe or angle style according to DIN or ANSI

- Top-entry version (standard)

- Metal bellows seal as protection against circulation inside the valve and icing up of the plug stem

- Protective cover to seal the cover flange during transport and assembly (optional)

Type 3246

- Suitable for cold-box use

- Versions in globe or three-way style according to DIN or ANSI

- Standard version with long insulating section and circulation inhibitor to protect the valve from icing up

Type 3251 in low-temperature version

- Versions in globe style according to DIN or ANSI

- With long insulating section

- For use in piping systems, e.g. in tank farms for liquefied gas

Self-operated regulators

Safety and quality are paramount when transporting and storing liquefied industrial gases.

The extreme operating conditions (pressures up to 40 bar and temperatures down to –196 °C) make it necessary to use special valves. The self-operated Series 2357 Pressure Regulators and Type 2040 Safety Temperature Monitors are especially designed for the conditions in cryogenic service.

The pressure regulators ensure that the tank pressure is right at all times, while the safety temperature monitors shut off any flow in case of emergency to protect the downstream pipe sections against impermissibly low temperatures.

Type 2357-1

- With safety function

- Can also be used as pressure reducing valve (without safety function)

- Type 2357-11: stainless steel version ultrapure gas service

- Integrated strainer

- Rugged design and low overall height

Type 2357-2

- For use as economizer

- With additional non-return unit (optional)

- Stainless steel version for ultrapure gas service (Type 2357-21)

- Integrated strainer

Type 2357-3

- Functions as excess pressure valve and pressure build-up regulator in one unit

- With safety function

- With additional non-return unit (optional)

- Versions for gas and liquid stages

- Stainless steel version for ultrapure gas service

- Integrated strainer

Type 2040

- They close when the actual value falls below the adjusted limit and when a sensor breaks and protect too cold control medium from entering the downstream consumers

- Typetested by TÜV

- Wide limit ranges from +10 to –45 °C

The following applies to all self-operated regulators listed:

Cleaning and testing according to international standards · Suitable for oxygen service · Type examination according to 2014/68/EU · Wide range of accessories available, such as welding ends, solder-on nipples and spare parts · Delivery with customized set points and limits possible

Liquid level, differential pressure and flow meters

The Media Series by SAMSON includes solutions for liquid level, differential pressure and flow measurement. The liquid levels and pressures that exist in the tanks are monitored and analyzed from the control room. As a result, the products can be supplied on time and in line with demand. At the same time, safety is monitored continuously.

The modular design of the Media series also facilitates attachment of valve block, operating pressure gauge and limit contacts.

Media 7 is capable of remote data transmission using a GSM module for communication with the SAM TANK MANAGEMENT.

Media 7

- Controlled by microprocessor

- Internal tank pressure sensor

- Modular power supply unit with standby power supply (SPS)

- Analog and digital inputs and outputs, 24 V supply voltage output

- 4” backlit graphics display

- Certified for zone 0

Media 5

- Indicator Ø 160 mm

- Customized scales

- Measuring ranges up to 3600 mbar

- Measuring range adjustment 1:2

- Zero adjustment from the front

- Can be fitted with three limit contacts

- Modular design

Media 05

- Indicator Ø 100 mm

- Customized scales

- Measuring ranges up to 3600 mbar

- Measuring range adjustment 1:1.6

- Zero adjustment from the front

- Can be fitted with two limit contacts

- Modular design

SAM TANK MANAGEMENT

- Precise usage data to achieve better predictions

- Improved delivery routes and scheduling

- Improved utilization of truck capacities

- Avoidance of costly overfills and empty tanks

- Safeguarding against dangerous pressure build-up

- Early warning before devices fail

- Scheduled and predictive maintenance

- Interface to ERP systems

- Smart sensors and ready-processed data