Intelligent, comprehensive solutions

Our quality standards

The quality of our products is the key to achieving customer satisfaction and to ensuring the long-term existence of our company and our customers‘ operations.

Our equipment and processes are extremely reliable and comply with major standards and regulations – beyond the minimum requirements.

Our state-of-the-art valves meet FDA, EC 1935/2004, 3A, EHEDG, ASME BPE and USP requirements. As a result, we can guarantee the highest purity level for your process and also the highest quality level for your products.

Tailor-made solutions

We can count on our long experience in process automation and offer you solutions from a single source that are perfectly tailored to the specific requirements of your application.

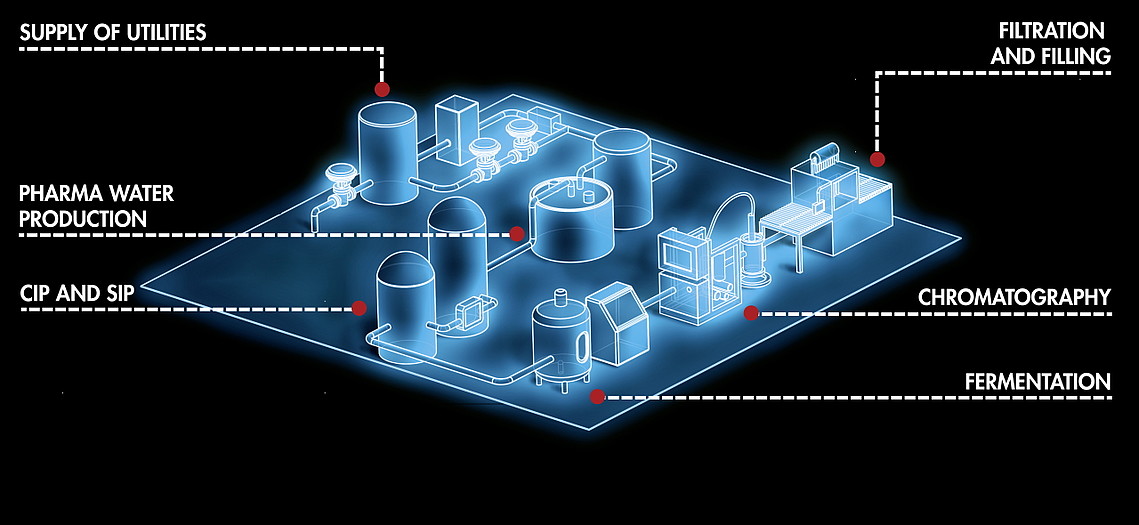

Whether it‘s hygienic, aseptic or industrial service, our proven equipment and services support you throughout the entire production process.

Our valves are successfully used in many pharmaceutical applications, such as fermentation or the treatment of pharmaceutical water as well as when mixing, distributing, dosing and filling the finished product.

State-of-the-art process engineering

Our product range includes aseptic diaphragm and seat valves to handle process media in the main process. Additionally, we manufacture diaphragm, seat, angle-seated, ball, butterfly and rotary plug valves to supply the plant with the required process utilities.

Compact electric, pneumatic and hand-operated actuators made of different materials are available to meet the requirements that apply in pharmaceutical environments.

A wide range of valve accessories, such as positioners, transmitters, compact controllers, limit switches, solenoid valves, travel limiters and supply pressure regulators, rounds off our product range.

CIP and SIP

CIP and SIP (Cleaning-in-Place and Sterilization-in-Place) ensure that the required levels of purity and sterility can be guaranteed, even without having to dismantle entire plant sections. Our aseptic seat and diaphragm valves made of stainless steel are suitable for handling high temperatures and corrosive CIP and SIP media, which reduces the need for maintenance.

Fermentation

Preventing the process medium from contamination is key to fermentation processes. Our diaphragm valves with CDSA-style seals make sure of that. On top, they control with high accuracy. Sterile bottom drain valves and sampling units guarantee that the fermented product stays safe while being processed further